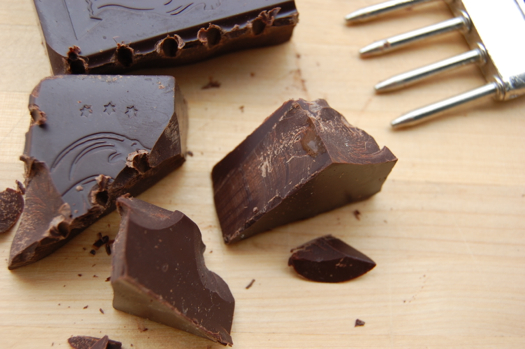

Milk Chocolate

Milk chocolate is the lightest and smoothest of all the major chocolate varieties, containing only about 10-20% chocolate liquor. It is the only type of chocolate that contains milk (or cream) solids, those take up roughly 15% of its volume. Milk chocolate is usually 50% sugar and the very smoothest varieties — you know, those very expensive Swiss bars — can be up to 30% cocoa butter. It all makes for a silky and delightful eating experience, if a decidedly less “chocolate-y” one. It’s for that reason that you don’t find terribly much milk chocolate in the pastry kitchen, as that small amount of chocolate liquor is easily lost when it’s used as a glaze or

READ ON